Would you like tea or coffee? About the choice of polymer shoes

Unfortunately, some sellers, as well as users of special shoes, do not fully understand the difference in the materials from which these shoes are made, and where these shoes are used. The approach to the choice of polymer shoes is very subjective and sometimes it is not entirely clear what criteria were used as a basis for conducting a tender and purchasing a particular shoe. Often, the only criteria are the cheapness and beautiful colors of the shoes.

Many use the concept of "rubber shoes" to mask any other shoes that look like rubber, but are made of different materials in terms of quality and functionality.

So, boots made of PVC, RUBBER, POLYURETHANE. So what's the difference?

Of course, each raw material for the production of shoes has its own merits, which manufacturers use to promote their products. The main users are enterprises that require waterproof footwear.

Each of the materials, be it PVC, PU or rubber, does an excellent job of moisture resistance. But in most cases, enterprises require additional protective properties, namely: dielectric, heat resistance, acid resistance, alkali resistance, oil frost resistance, oil and gasoline resistance, protection against mechanical damage, anti-puncture insole, anti-shock tray. Important factors are also important: the weight of the boot and sliding at negative temperatures.

It is important to know that these characteristics are mainly inherent in rubber shoes. Yes, yes, it is made of rubber, no matter how trite it sounds. Let's understand the protective properties of each of the materials.

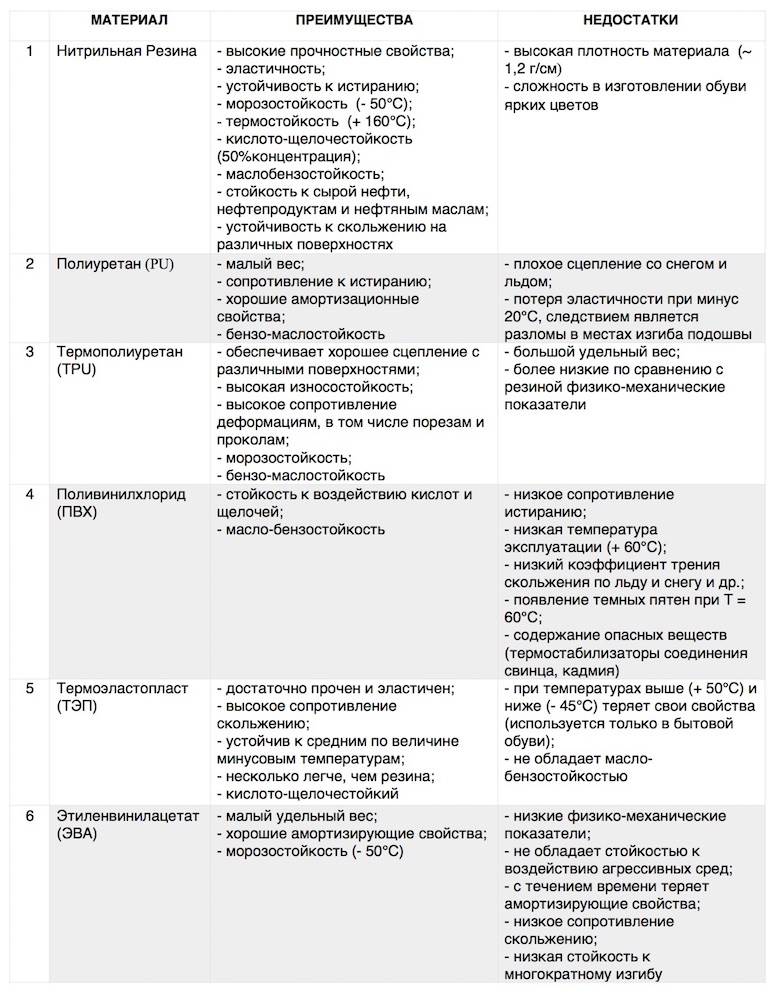

For complete objectivity, we will conduct a professional comparison of the technical characteristics of known materials: rubber, PVC, PU, TPU. So we will close many questions.

Very often, manufacturers of polymer shoes, especially PVC shoe manufacturers, "appropriate" the characteristics of rubber, work on stereotypes in the minds of consumers. Sometimes it gets ridiculous: some "sellers" write and say that rubber is a thing of the past, and now the latest development is rubber shoes. Obviously, these sad sellers do not have basic school chemistry lessons. (Rubbers are the main component of the resin composition). If you look at the websites of such manufacturers, you can read — Rubber shoe factory. You go to the site, and there is PVC or EVA, it doesn't even smell like rubber. It's the same story with "conscious" misinformation of consumers by online stores: in the product description they write "rubber boots or rubber shoes", but in reality it's all the same PVC or EVA. And it seems that special properties of shoes are not needed here, but this is at least an introduction to misleading buyers. Obviously, this is easier to convey to the buyer: rubber means moisture-resistant.

Such a variant of disinformation has no right to exist in any industry, including the production and sale of special shoes. For example, TEA and COFFEE. It seems that both of them are drinks, but their properties, taste and aftertaste are completely different. No one would think of selling tea under the guise of coffee. And in production, this can lead to serious consequences.

In some corporate regulations of large state and private companies (especially in the oil and gas industry), and, as a consequence, in tenders, in the nomenclature of applications, "Rubber PVC boots" are written. Yes, yes, this is exactly how the application for shoes is submitted: without a comma, without any semantic separation. But these shoes are completely different in terms of characteristics!!! Rubber - that means from rubber, a PVC - made of PVC. I really want to ask such applicants: So what do you need? Tea or Coffee?! This is, at the very least, unprofessional, and, at the most, simply ignorance of the subject. And, if boots made of Rubber, PU, TEP, according to their characteristics, belong to special shoes, then PVC shoes do not have such "extreme" properties and are suitable mainly for protection against OPZ (general production pollution). As a result, serious enterprises buy different-colored, cheaper shoes that do not have sufficient protective properties!